Why Operational Data is Key For Compliance & ESG

At the most recent NAEM EHS Forum, we heard from EHS professionals from around the country that feel like they’re being pulled in two different directions. On the one hand, executives are increasingly interested in ESG and how it affects the business’ profitability. On the other, there are still the day to day issues of complying with OSHA, EPA, and other regulations. The good news is that operational data is the key to succeeding with both. It’s also more widely available than ever before.

What is operational data?

Simply put, operational data is the data gleaned from an organization’s day-to-day operations. This includes everything from equipment performance and maintenance reports, to process data and information about production activities, to near miss reports and incident logs. Some people also refer to this as “shop floor” data.

Why is operational data important for compliance?

Having access to complete, accurate, timely operational data is key for compliance. This is true for everything from worker safety to air emissions. Without data on these operational issues, there’s no way to prove that you’ve conformed to regulatory requirements. Should you find yourself in violation, the best thing for your business is to be able to prove that everything that could have been done, was done.

In addition to proving compliance to regulators, operational data also provides EHS professionals a real-time understanding of performance so they can make better decisions about compliance. Which activities are resulting in accidents? Where are the risks? These are all questions that this data can answer, which in turn leads to better compliance.

What about regulatory changes?

Of course, the regulatory landscape is always changing. New regulations pop up every day while old ones get revised or repealed. You’ve likely seen this reflected in laws like the Clean Air Act or OSHA’s COVID-19 ETS.

Real-time operational data is what enables organizations to adapt to these changing regulations. Because they have access to information about the current state of things, they’re able to pivot quickly when new regulations come out. This might mean ramping up compliance efforts to meet new demands. It may also mean simply slicing and dicing operational data in a different way for reporting.

Why is operational data important for ESG?

Today, there are a number of different ESG reporting frameworks. These include CDP, GRI, SASB, and TCFD, to name a few. Each reporting framework has its own metrics and reporting standards.

Fortunately, companies that are tracking a broad range of operational data already have what they need to be able to report against these standards. And when new ESG standards come out, such as those from the ISSB or SEC, companies that have access to operational data will be able to use the information they already have in their database to fulfill new reporting requirements.

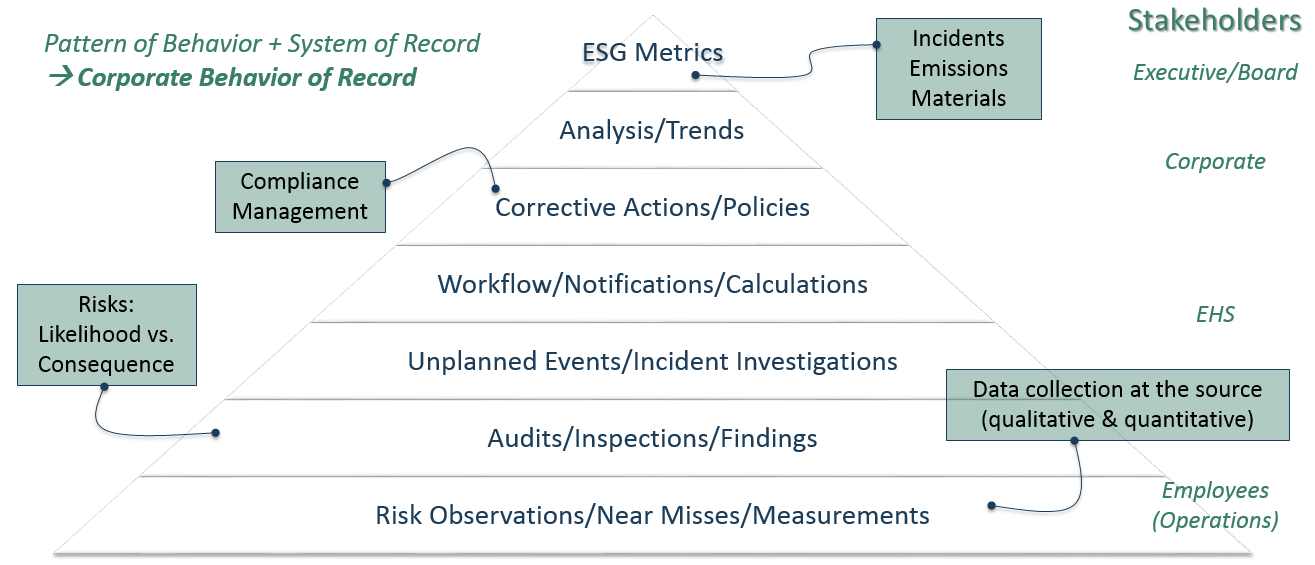

Data such as risk observations, near misses, and measurements is collected at the source. This data can then be rolled up into ESG reporting.

What about ESG risks?

Of course, an effective ESG strategy goes way beyond reporting. It’s about managing new risks and opportunities — and operational data is the key there as well. Because it is collected at the shop floor level, operational data is usually very granular in nature. This helps create an accurate picture of environmental, social, and governance issues, which in turn helps decision-makers identify ways to take ESG performance to the next level.

If you’re a manufacturer, for example, having access to data about energy use at the equipment, production line, or asset level allows you to pinpoint areas with the highest probability for reduction. Likewise, if you’re a construction company, having access to employee near miss reports and risk observations can help you make informed decisions about employee safety and other areas that directly impact ESG performance.

What are the challenges of operational data?

The good news is that it’s never been easier for organizations to collect operational data. Automated tools like equipment sensors and wearable PPE have made it possible for organizations to capture data about EHS risks and performance around the clock. Add to that the widespread use of mobile apps that enable frontline workers to report safety hazards, and organizations are now able to easily create grassroots, data-driven cultures involving all employees at all levels of the organization, every day.

But while companies might be able to aggregate lots of data, many of them still struggle with putting the information to use. Operational data only brings real value if it is able to be used and can deliver insights. This is challenging for a few different reasons:

Data sources

One challenge is the sheer number of sources. All of the information gathered from sensors, smart devices, and apps usually ends up scattered all over the place.

To succeed with operational data, organizations need a way to centralize and integrate all of this info. This is done by implementing a centralized, comprehensive EHS software system integrated with your enterprise systems. An EHS software system acts as an operational data store, bringing all this information together in one place so it can be analyzed to reveal important insights.

Data visibility

This ties into another problem: In order for operational data to be useful, it must be timely. But because this data is often so spread out, it may take days or weeks for reporting. Today, 53% of manufacturing and industrial operations lack real-time visibility into EHS performance data, according to LNS Research.

Without timely operational data, organizations risk making decisions based on out-of-date information. In turn, this can lead to non-compliance and harm sustainability efforts. Once again, this underscores the importance of having an EHS software system that can provide real-time data analytics for visibility into operations data.

Your takeaway

Unlocking this data is the key to succeeding with both compliance and ESG. While the exact rules and reporting requirements might change, the basic principles that worked in the past still work today.

It’s less about reinventing the wheel and more about doing the things we already know are effective — namely, collecting complete, accurate operational data and making it available to the right people at the right time.